5 Ways Lean Mobile Workstations Boost Shop Efficiency

Labor shortages. Tight cycle times. Higher repair complexity. Today’s shops need smarter workflows, not just more hands on deck.

That’s where lean mobile workstations come in.

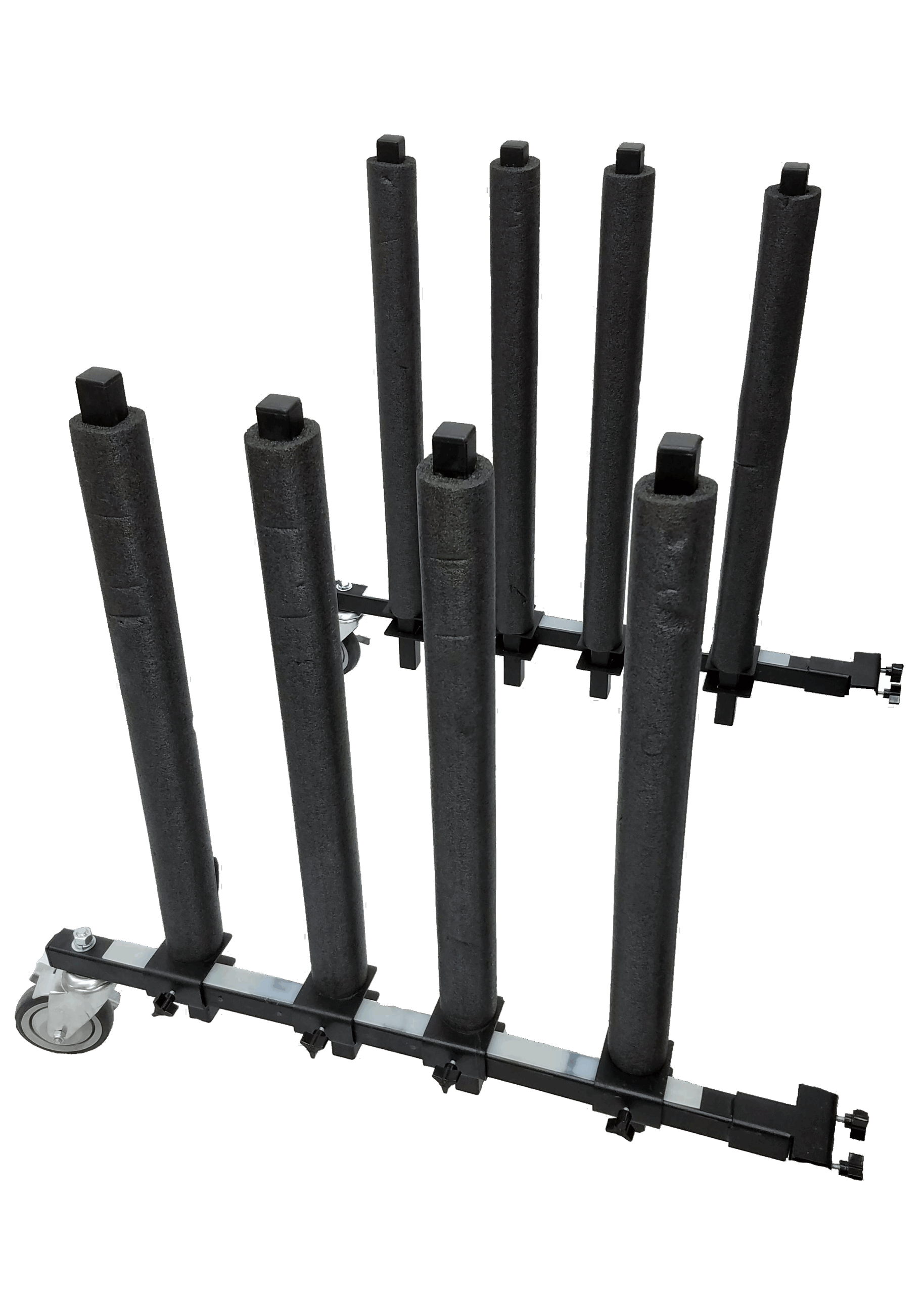

Whether you’re tearing down, painting, or detailing, a well-designed cart does more than move tools. It eliminates chaos, supports accuracy, and lets techs stay focused on what matters most: the repair itself.

1. Eliminate Wasted Motion

Walking back and forth for supplies, tools, or paperwork eats up valuable time.

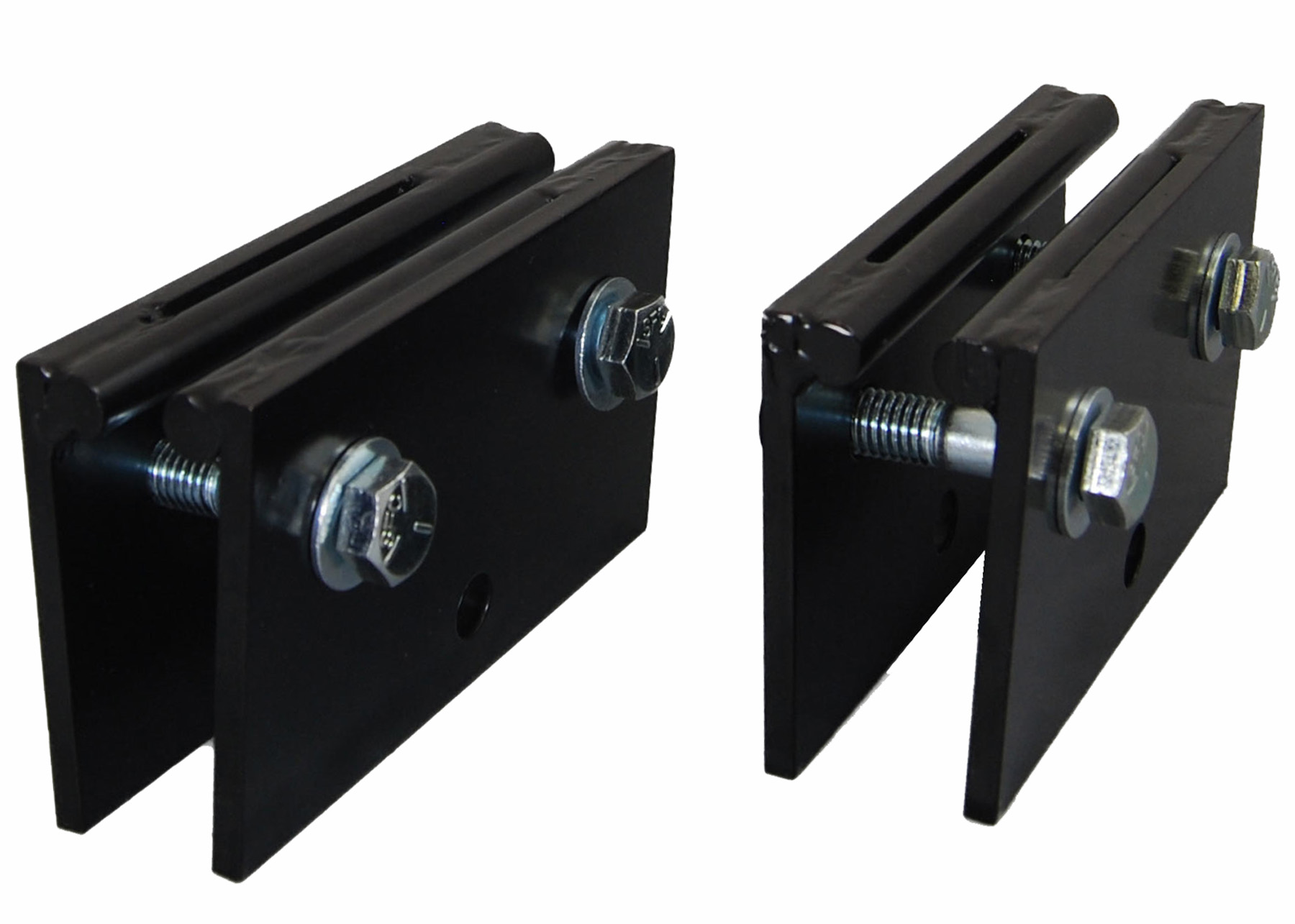

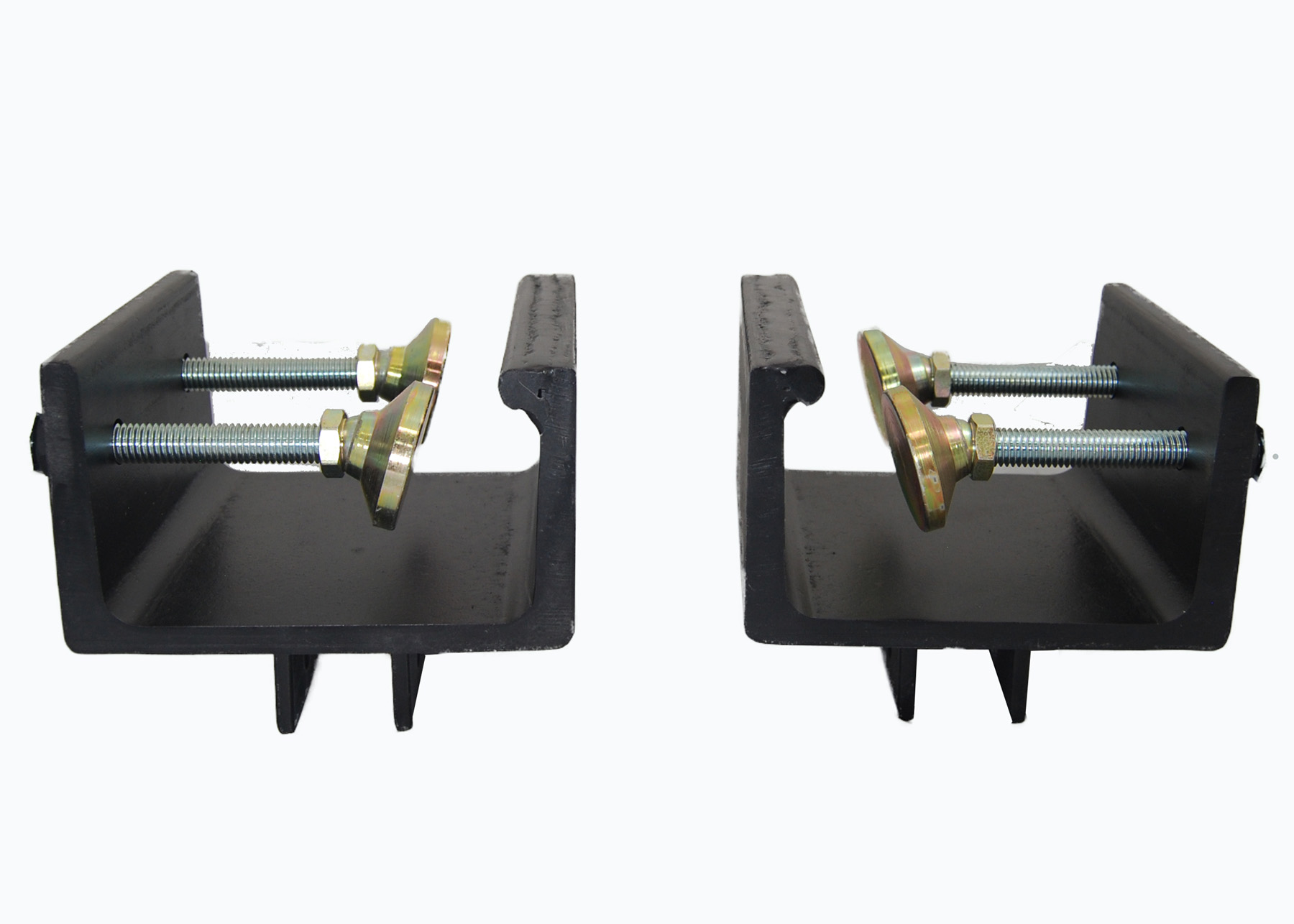

Lean carts like the G1 Go Cart bring everything to the vehicle, reducing time lost to steps and searches.

2. Keep Tools Organized & Accessible

Open shelves lead to clutter. Smart carts use compartments, dividers, and mounts to give every item a home so your team spends more time fixing, less time finding.

3. Support Digital and OEM Procedures

Goliath carts are built with power ports, cable routing, and secure mounting so your techs can scan and calibrate efficiently.

4. Standardize Your Workflow

Consistent cart setups help new hires ramp faster, and ensure repeatable results across teams. Whether it’s a P1 Paint Cart or D1 Detailer, Goliath helps bring order to every department.

5. Reduce Losses and Downtime

Ready to Streamline Your Shop?

Goliath carts are more than mobile storage, they’re lean workflow solutions that boost productivity in real-world shop environments.

Need help choosing the right setup for your team?

Call us at 866.694.2278 or contact us online.